Sustainable Management

We are committed to advancing a sustainable future by actively practicing green management,

social responsibility management, and compliance management.

EnvironmentㆍEnergy Administration System

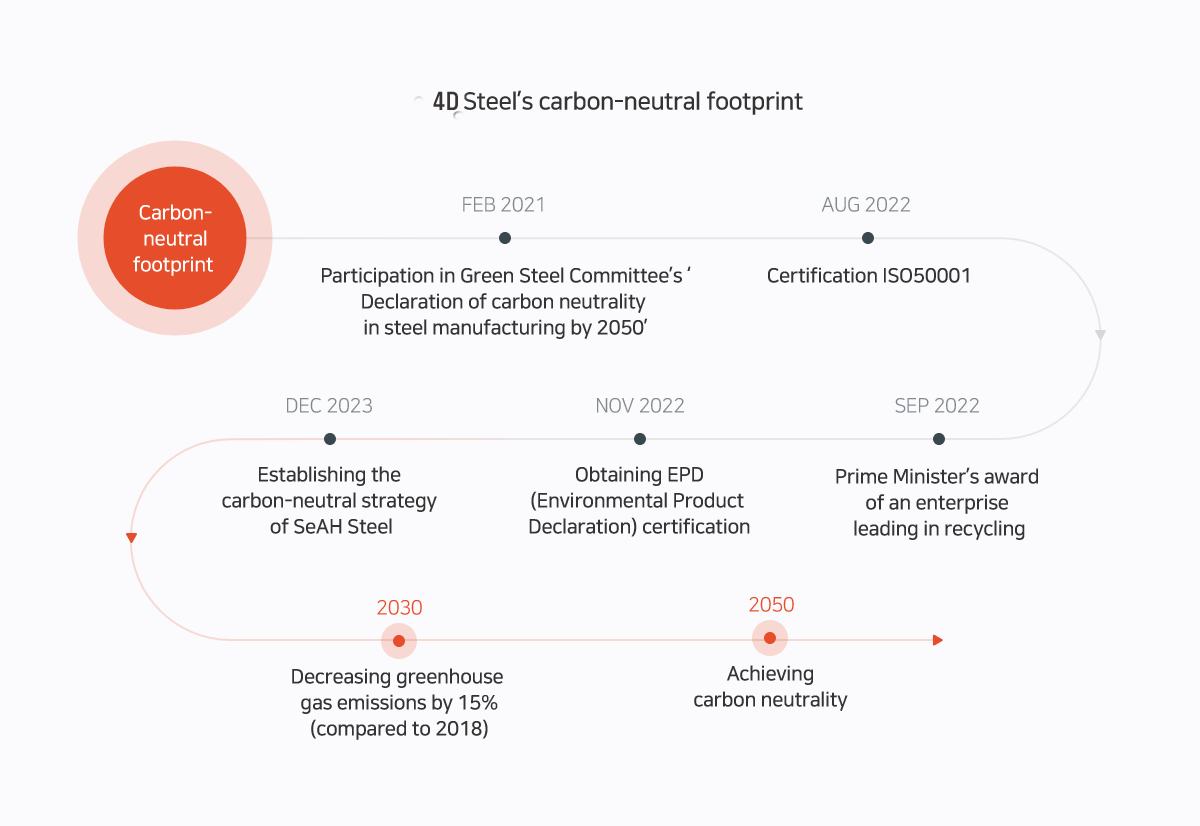

4D Steel is creating sustainable environment management throughout product manufacturing by implementing environment and energy management systems (ISO14001, ISO50001). Moreover, all members participate in environmental CP (compliance program) aimed at resource circulation, abiding by environmental law, and preventing environmental accidents. Alongside that, through developing an independent integrated system SHE, we manage environmental data on the whole and actively respond to environmental regulations.

EnvironmentㆍEnergy policies

Regulating air-polluting substances

4D Steel keeps air-polluting substances under the level determined by law, established investment plans for the environmental sector, periodically assesses the results, and executes them to improve justice at all factories and implement sustainable environment management. Moreover, to reduce bad smell and THC (total hydrocarbon), we control it in real-time through direct combustion installations (RTO and TO) and telemonitoring systems (TMS) and minimize air-polluting substances.

Regulating water-polluting substances

Water-polluting substances produced during the manufacturing process are primarily processed using physical and chemical methods, and wastewater containing nitrogen is processed biologically in wastewater treatment facilities and let out in the nearby waters to minimize the impact on the nearby sources. Wastewater processed primarily and secondarily is gathered at the ultimate wastewater treatment facilities and, after being processed for the third time, is let out in quantities less than the standard designated by law. 4D Steel is aware of the importance of protecting water bodies near the workplaces and will strive to find the optimal way to conserve water.

Regulating waste

4D Steel is striving to minimize the environmental impact of waste by keeping pace with the changing paradigm of waste, with more than processing it according to standards required by law but reducing and recycling it. We conduct provider evaluations to choose providers with a confirmed trustee capacity while choosing a waste transportation and processing enterprise and actively provide harmful information materials about managing waste, letting the involved parties know what to pay attention to while working with waste. The results of these activities gained recognition and we were chosen as a distinguished enterprise leading in recycling and received an award from the prime minister. Moreover, we consistently perform activities to promote awareness about resource recycling, such as active separated disposal and recycling of waste, education for workers about garbage, etc.

Regulating chemicals

Through regular examinations, thorough inside education, etc., we prevent accidents caused by chemical spills, and through conducting periodic emergency training, we also thoroughly provide against accidents caused by chemicals in case of emergency. Moreover, we prevent accidents caused by chemicals by constructing and running sensors and CCTV for chemical spill prevention at facilities that treat them and emergency withdrawal systems, attaching Material Safety Data Sheets (MSDS), safety display panels, etc.

Regulating energy

4D Steel has established an energy center that monitors energy use in real-time, manages the data, and, by analyzing it, identifies the elements to reduce and improve illogical elements. Through electric power demand management (DR), we also participate in reducing the electrical energy peaks and are planning to systematically analyze the energy use and conduct energy optimization and carbon reduction activities through building factory energy management systems (FEMS).